Creo Training Courses

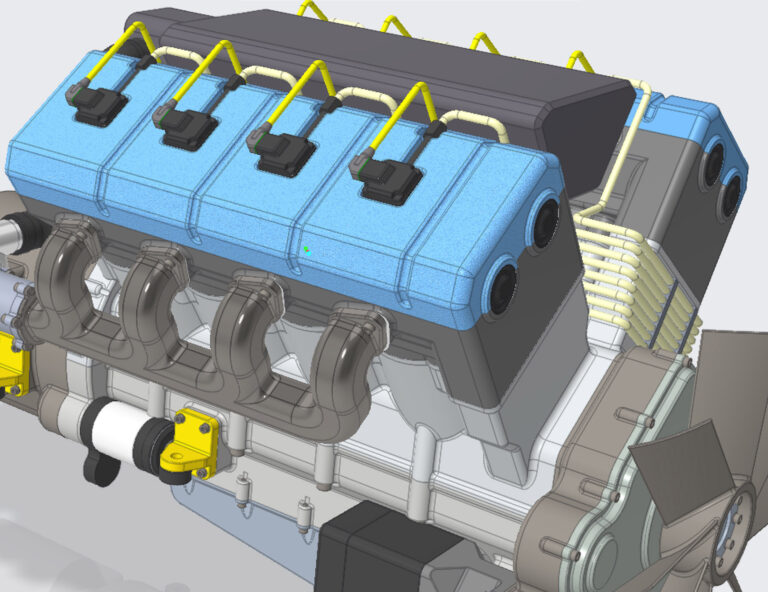

With Design Engine’s proven Creo training techniques, we intend to empower manufacturers, engineers, and designers to gain an impressive smarter perspective by presenting new ways to think about and explore design. Let us help you make for faster design developments & Learn to be more effective at updating iterations. Be smarter as a team member…. faster, smarter, better, and more efficient all in these powerful Creo training classes.

Learn to design with Creo

Intro to Creo Training

Advanced Assembly Intensive

Creo Sheetmetal

Cable harness design Week Two

Mechanism Dynamics Intensive

Creo to SOLIDWORKS or SOLIDWORKS to Creo: A Week Long Intensive

Learning Creo for Industrial Designers

Creo Pro/Program

Detailed Drawing and Assembly

Top-Down Design

Advanced Creo Sheetmetal

Schematics Training

Flexible Modeling Extension FMX

Design for Additive Manufacturing

Creo Update Training

Creo Four Week Comprehensive

Rendering with Creo & Keyshot

Advanced Modeling

Advanced User Custom Training

Cable Harness Design Week One

Import Data Doctor

Behavioral Model Extension

Mold design

CREO MILL PROTOTYPING

GD&T Training

Interested in Creo training?

We don’t just teach Creo classes, we teach ways of thinking. With our Creo training classes, we offer you more of a product design course. Design Engine’s passionate and knowledgeable staff have decades of design and engineering experience. Therefore, we are able to share unique ways of solving problems by going beyond the Creo software itself. For instance, with Design Engine’s style of Creo learning, you’ll dive into design problems, allowing your team to learn quickly, and more efficiently.

All of Design Engine’s Creo training programs utilize customized training material with an engaging focus on core-modeling skills and putting design problems into context, with respect to the manufacturing process. These packages can be tailor-made to you or your team’s immediate design needs, whether it is overcoming problems in the software, current project design obstacles, or pushing past what you thought you were capable of doing, Design Engine will help.

Design Engine as a training organization exists because you recommend us. Thank You! We are committed to helping your staff work smarter and more efficiently. We communicate effectively in our CAD tools, we think you should as well. We are here to help you be a better communicator!

Design Engine Creo Training revolves around design & manufacturing & the team

We specialize in using Surfaces as tools or managing light reflection or ergonomic design. We also specialize in manufacturing with our Die-cast, Plastic Part Design, or Forging and Sheet Metal in Manufacturing all while using Creo; FEA for assemblies; Cable Harness; Detail Drawings, advanced assemblies with top-down design, and many other Creo training classes. Consider that we discuss successful ways of quoting a project, managing your manager’s expectations, approaching and defining the project scope, modeling tips & tricks, making changes and adjustments within projects, cohesive communication strategies between designers and engineers, innovations with new manufacturing processes, managing ECNs, and storing project files…. All to make you or your team more productive. Our Creo training workshops don’t just teach how to solve design challenges, but they change the way designers think, setting off a chain reaction: fostering collaborative relationships, exploring a new design process, facilitating better communication, encouraging problem-solving, and, most importantly, challenging mechanical engineers and product designers to grow and innovate. Consider a Creo training regiment with Design Engine and email us now.